ABOUT US

Established in 2006 we manufacture high quality, complex and simple CNC turned and milled components in all metals and plastics.

Originally based in Birmingham, we moved to Aldridge in 2012 to larger premises. We have recently relocated to Shenstone almost trebling our floorspace.

We can manufacture turned parts from 0.5mm diameter to 300mm diameter in quantities from one off prototypes to production batches of thousands.

Our machining centres have the capability of machining components only a few millimetres square up to over 500mm square whilst still holding fine tolerances.

Components are manufactured in a wide variety of materials including nylon, acetal, hdpe, peek, vespel, aluminium, steel, stainless steel, copper and many more.

The inspection department was also upgraded when we moved. We now have a full CNC coordinate measuring machine enabling us to automatically inspect 3D and 2D components to micron tolerances and compare them against 3D models and CAD files.

It is our mission to continue to invest in new CNC machines and the latest technology to meet the increasing demand for both simple and complex components machined to high standards with short lead times.

MANUFACTURING SOFTWARE

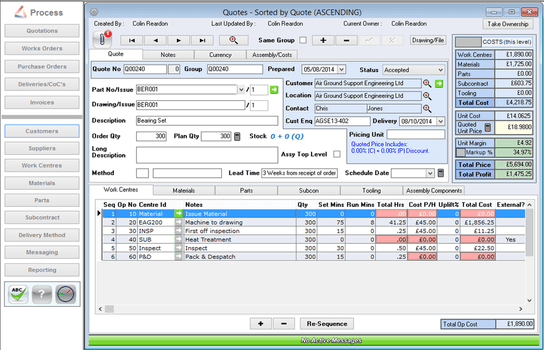

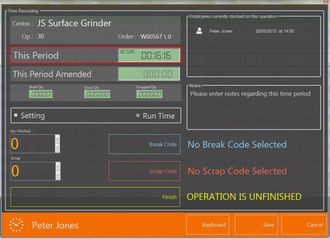

Tricorn Systems provide and support our production control software. The software is deployed and utilised through out the factory and is used for everything from quotations and works orders to stock control and invoicing.

We also have the scheduling module and shop floor data capture to enable us to perform detailed planning and see the progress of any job in real time.

Our manufacturing software is also incorporated directly into our quality management system using Tricorn's QMS module. This lets our business store and organise all of our quality documentation and records in one place and is integrated into the production system.

CAD CAM

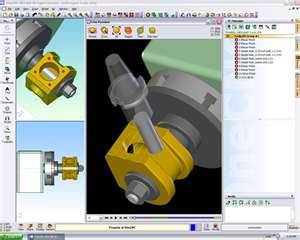

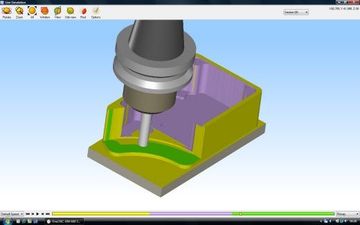

To compliment our machining centres we continue to upgrade our 3D CAD CAM packages allowing us to import all major 3D drawing package models and CAD files.

We have multiple seats of ONE CNC XR6 enabling us to program in the drawing office and directly on the shopfloor.

ONE CNC allows us to draft in 2D and 3D and fully 3D machine using 3, 4 and 5 axis with full part simulation.